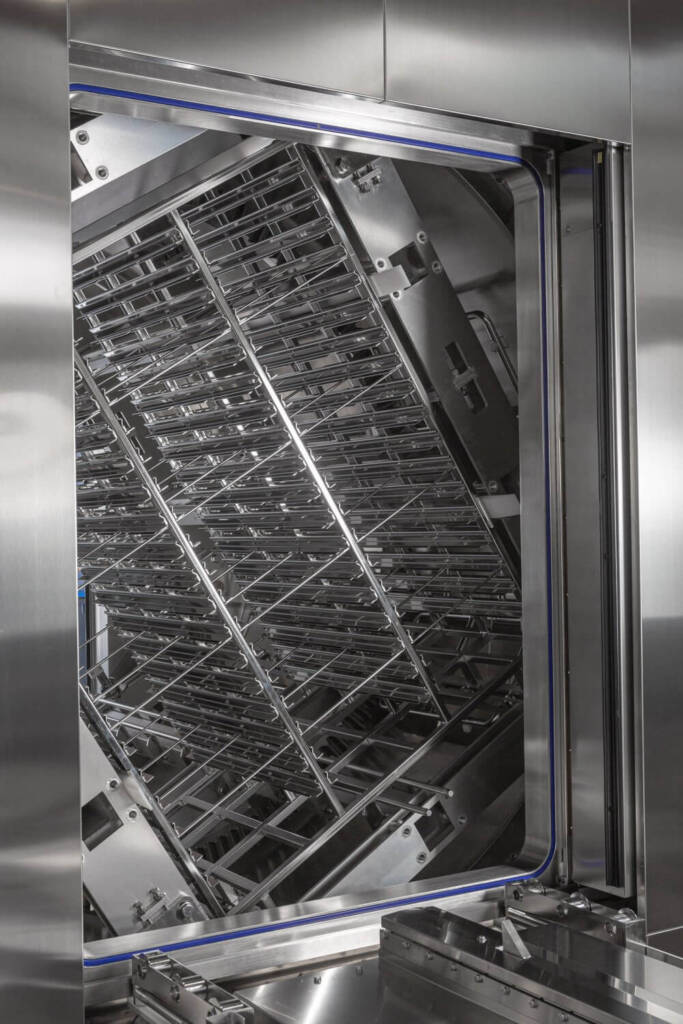

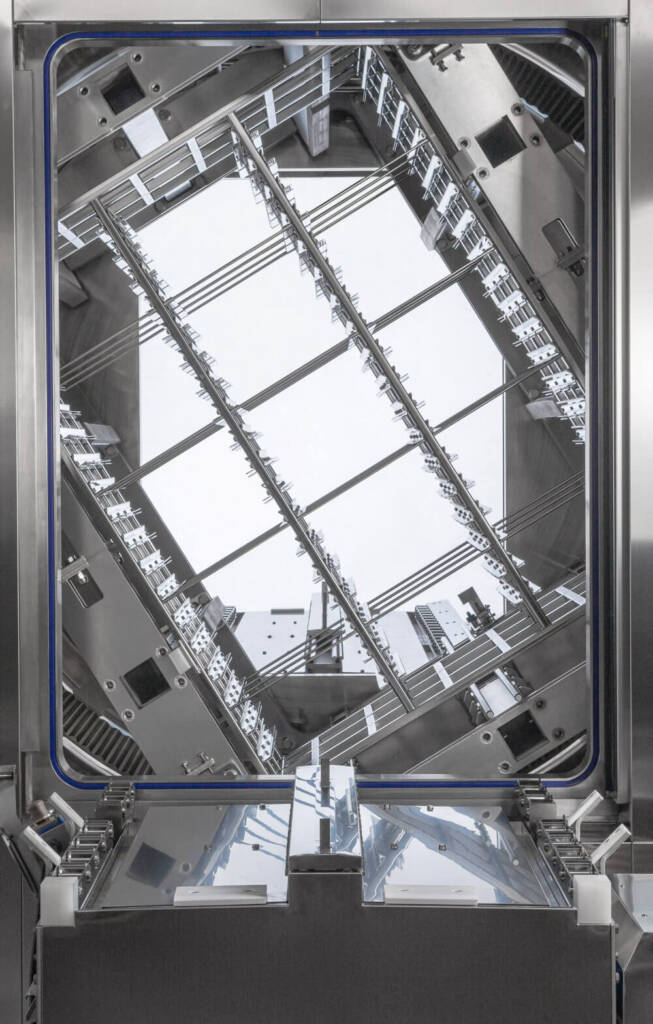

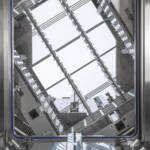

- Circular sterilisation chamber with square or rectangular hatches (doors).

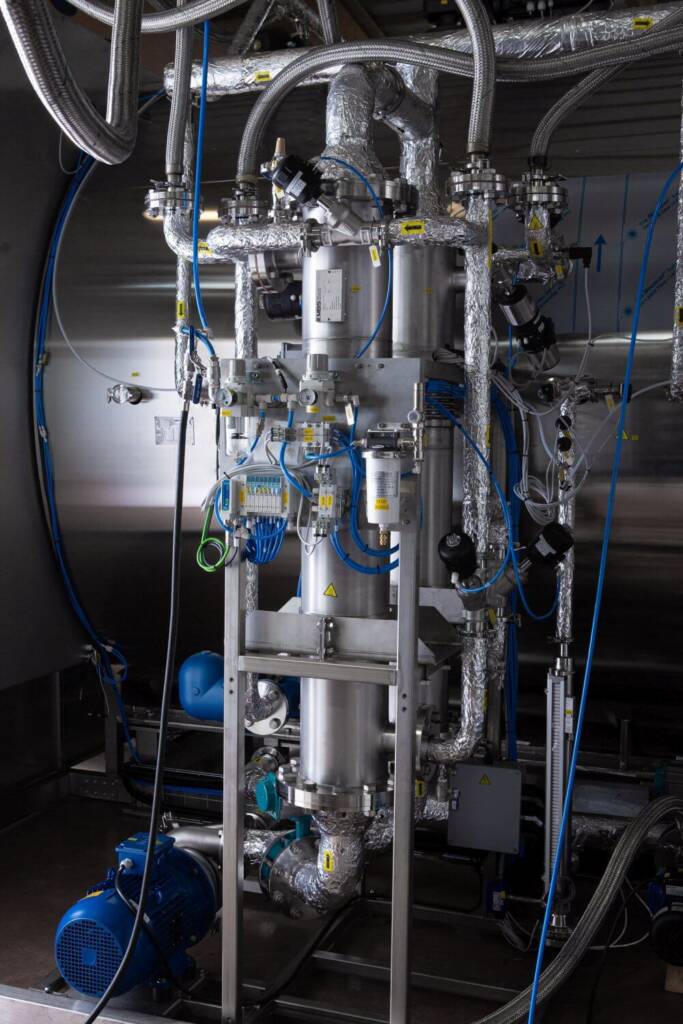

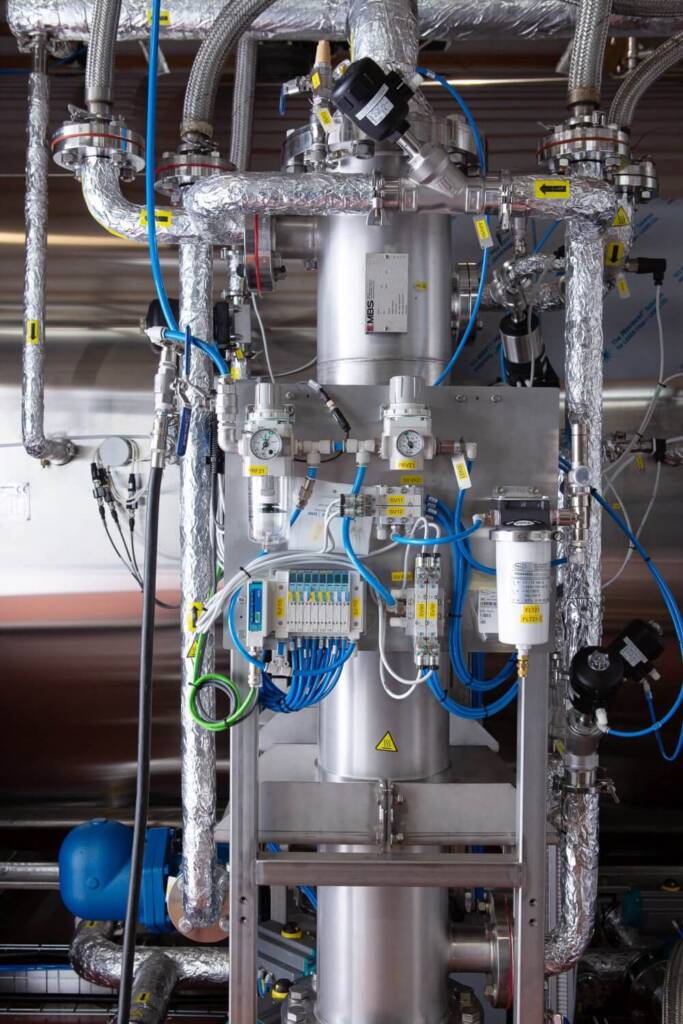

- For the air + steam mixture process, a flat/circular cavity completely wraps around the chamber for rapid and uniform heating/cooling of the loads.

- For the superheated water process, the chamber is with single lining (without cavity).

- The chamber is positioned on a base that has been designed specifically to evenly distribute the weight on the floor.

- Internal structure for rotation of the load with electrical-mechanical drive.

- The bottom of the chamber converges towards the drain sump to facilitate the disposal of condensation and water.

- Two 2” tri-clamp ferrules are welded to the chamber for validation purposes (temperature uniformity mapping and pressure tests).

- All of the chambers internal surfaces are mechanically polished and then subjected to chemical degreasing, pickling and passivation treatments. Surface finish: ≤ 0.35 micron.

- Above-floor or recessed chamber installation possible (depending on the size).