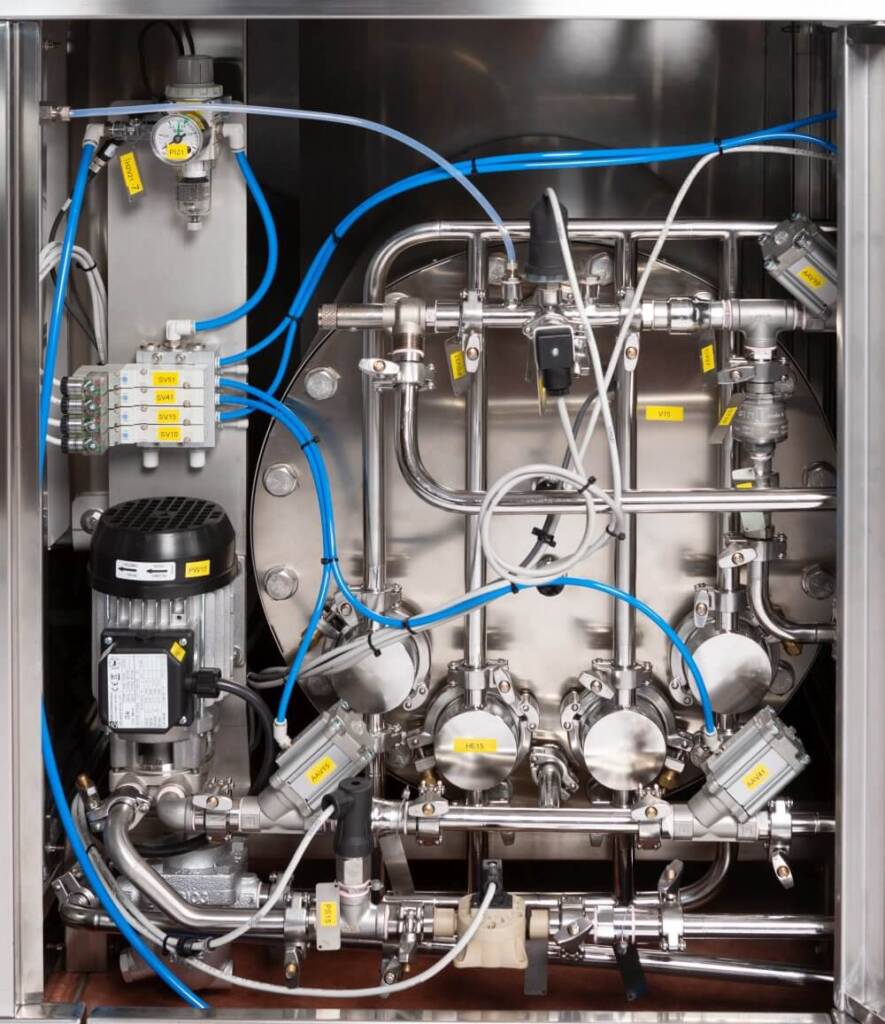

- Circular container with a circular inspection flange (aka. “double-headed”).

- The heating elements (electric heating elements or “coil” tube bundle for indirect heating) are housed directly on the inspection flange.

- The container is positioned on a base that has been designed specifically to correctly distribute the equipment’s weight on the floor.

- The bottom of the container converges towards the main condensate drain.

- The container is equipped with1.5” tri-clamp ferrules for validation purposes.

- The internal surfaces, piping and all parts that come into contact with the product are mechanically polished. Ra finish: ≤ 0.35 micron.

- 0.2 µm cartridge filter integrated on the clean steam line (optional).

- Water separation device installed on the clean steam inlet line to ensure that the generated steam is saturated (free from condensation) [optional].

- Floor-mounted generator.