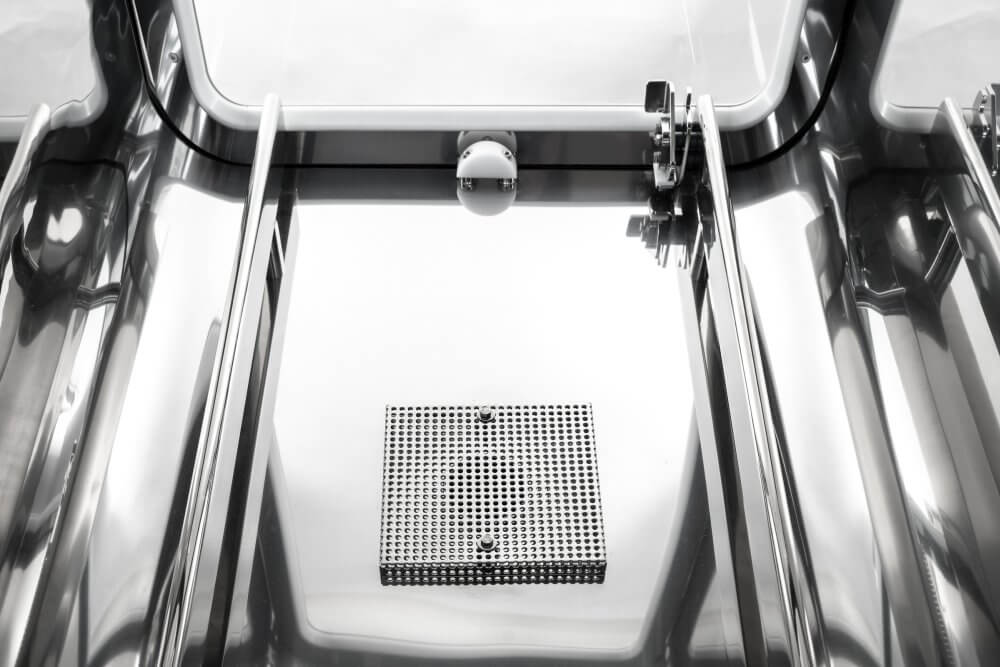

- Square or rectangular washing chamber and hatches (doors).

- AISI 316 L chamber and doors.

- All the edges are rounded to ensure optimum surface hygiene.

- The “U”-shaped reinforcements welded on the outside of the chamber ensure its stability.

- The internal ventilation system ensures that the hydrogen peroxide is optimally distributed on the load.

- Catalytic chamber degassing system.

- The pass box chamber is positioned on a tubular-type base to evenly distribute the weight on the floor.

- The loading trolley-inserting and removing guides are positioned on the bottom of the chamber. These guides are also height-adjustable.

- Two 1.5” tri-clamp ferrules are welded to the chamber for validation purposes.

- All of the chambers internal surfaces are mechanically polished and then subjected to chemical degreasing, pickling and passivation treatments. Surface finish: ≤ 0.35 micron.

- Above-floor or recessed chamber installation possible for large volumes.

- The unloading door has been designed to be connected to the walls of the clean chambers (“Bio-seal” interface).