- Circular, quadrangular or rectangular sterilization chamber with quadrangular or rectangular hatches (doors).

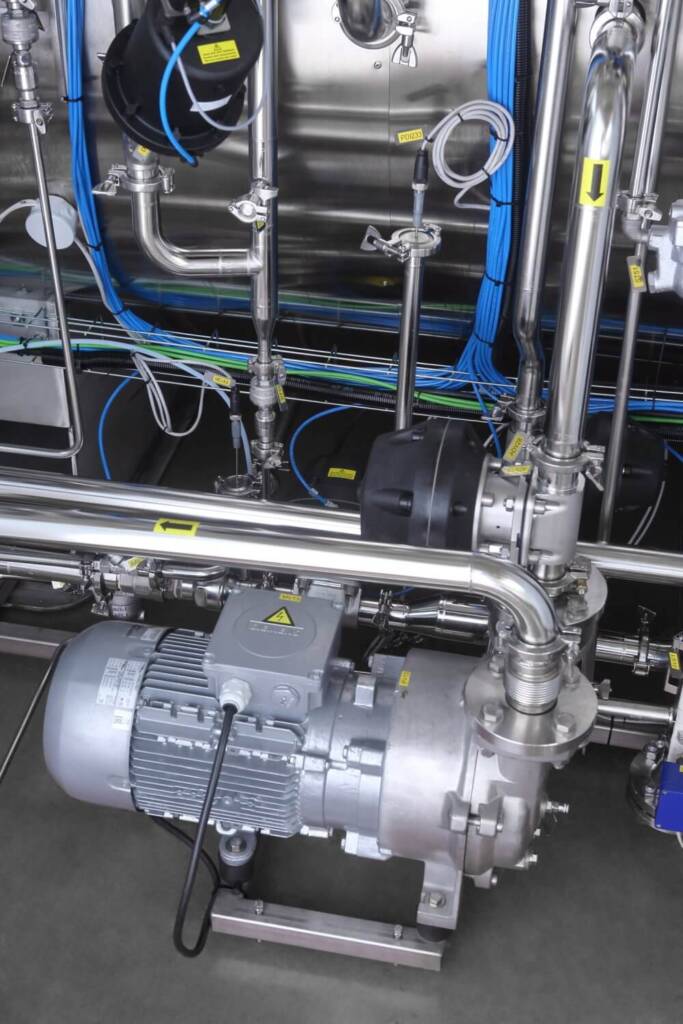

- An ashlar-type cavity completely envelopes the chamber to quickly and uniformly heat/cool the loads.

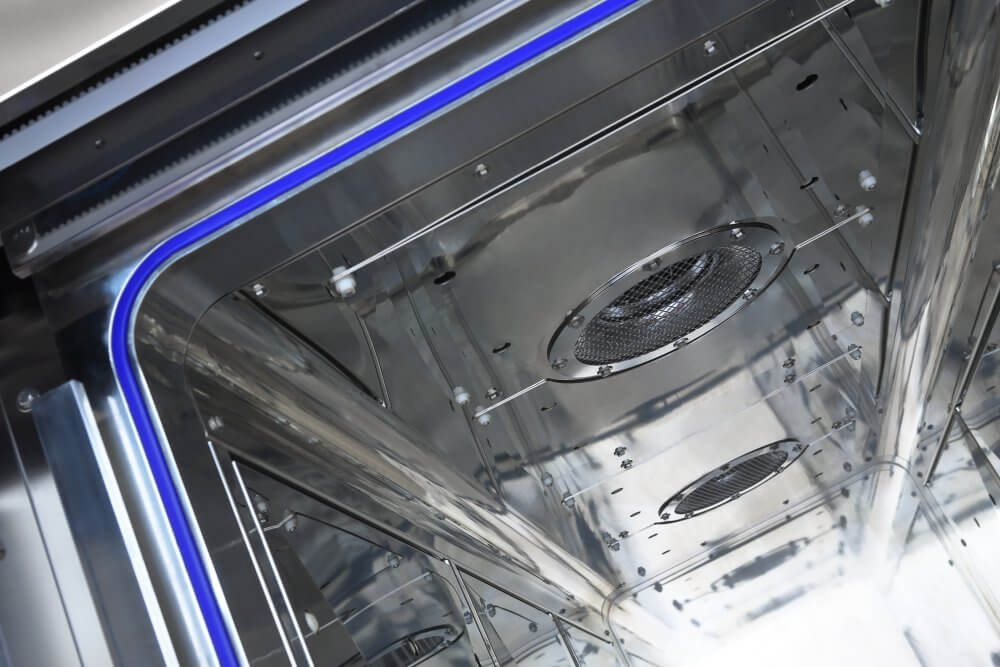

- Fully welded one-piece chamber with rounded corners to ensure excellent hygiene levels and facilitate internal surface cleaning.

- The mechanical construction is resistant to temperatures above 140°C.

- Some reinforcements are welded onto the outside of the cavity to ensure stability during operating conditions.

- The chamber is positioned on a tubular-type base to evenly distribute the weight on the floor.

- The loading trolley-inserting and removing guides are positioned on the bottom of the chamber; they are also height-adjustable.

- Two 1.5” tri-clamp ferrules are welded to the chamber for validation purposes (temperature uniformity mapping and pressure tests).

- All of the chambers internal surfaces are mechanically polished and then subjected to chemical degreasing, pickling and passivation treatments. Surface finish: ≤ 0.35 micron.

- The bottom of the chamber converges towards the drain sump in order to make disposing of the condensate easier.

- Above-floor or recessed chamber installation possible (depending on the size).

- Both doors (loading and pick-up side) have been designed to be connected to the walls of the clean chambers (“Bio-seal” interface).